Japan’s Proven Strategies for Robotics and Manufacturing Automation Excellence in Global Supply Chains

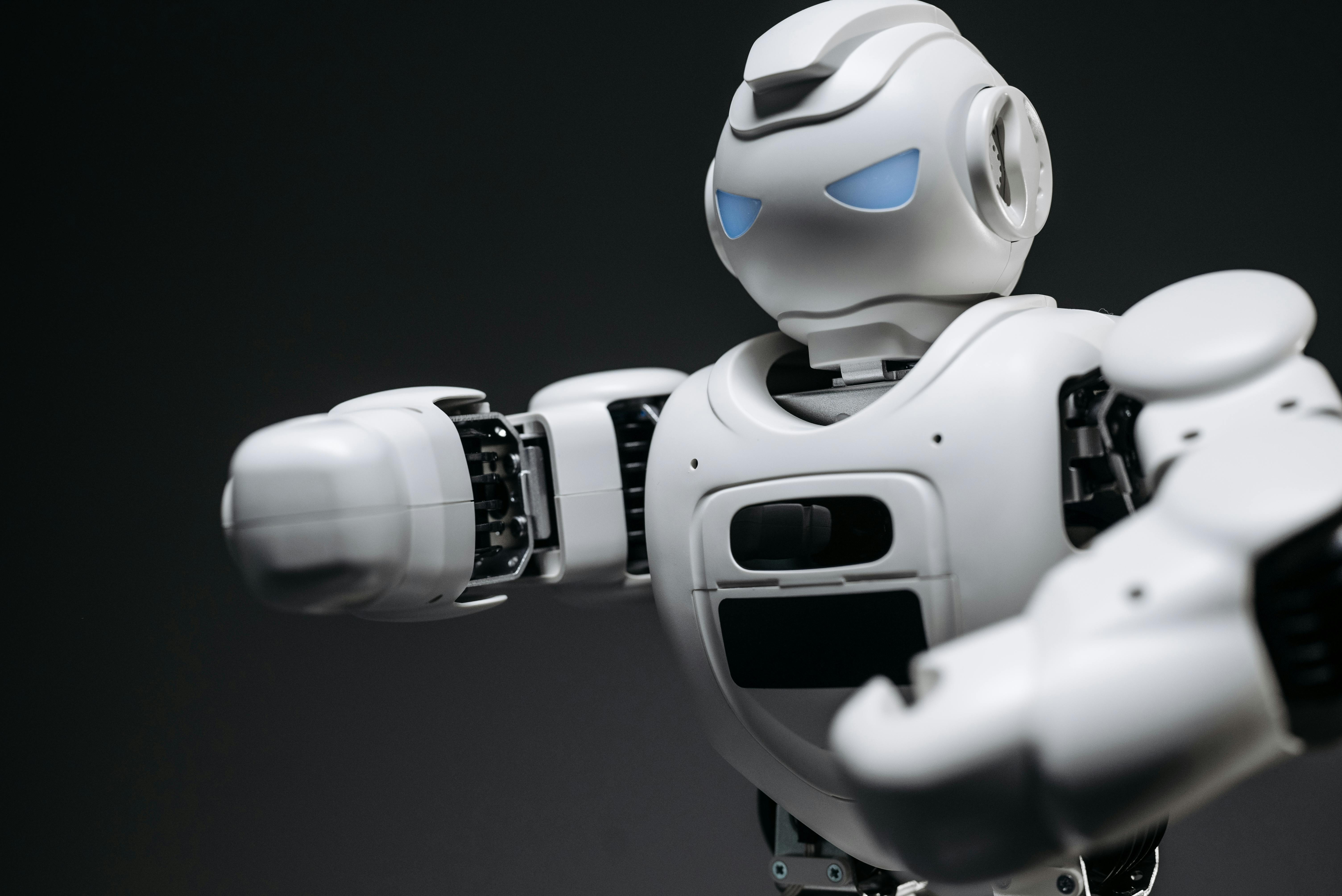

Let me begin with something a bit unexpected: in late 2019, I found myself standing on the production floor of a Japanese automotive plant in Tochigi prefecture. The hum of coordinated machinery, dozens of robot arms moving in perfect sync—what struck me most wasn’t just the technical sophistication, but the subtle choreography of human and artificial intelligence, born from decades of relentless kaizen, or continuous improvement. Honestly, I’ve spent years working with automation rollouts in Europe and North America, but walking that floor changed my understanding of what it means to achieve true manufacturing excellence. Japan’s approach to robotics and automation isn’t just about technology—it’s a philosophy embedded into every layer of the operation.1

Over the past four decades, Japanese manufacturers have quietly perfected a suite of robotics and automation strategies that underpin global supply chain stability—even during turbulent years like 2020. While many talk about Industry 4.0 or the rise of smart factories, what fascinates me is how Japan’s methods remain strikingly relevant and adaptive as new challenges emerge. Ever wondered why Toyota, FANUC, or Panasonic consistently lead both efficiency and resilience metrics? There’s more to it than shiny machines or budget spend. In my experience, and what keeps coming up in trade journals and conference panels, is a unique blend of cultural discipline, process engineering, and daring innovation.2

Strategy 3: Modular Automation & Flexibility

What I should have mentioned earlier—Japanese manufacturers are notorious for avoiding “one size fits all” automation. Instead, the norm is modularity: designing automation systems that can evolve, swap components, or reprogram AI logic without shutting down production. After a decade in supply chain consulting, I’ve come to realise that this approach is more than efficiency—it’s a shield against market volatility.8

Did you ever try to retool a European automotive line for a sudden part change? Unless it’s Japanese-designed, it often takes weeks. In Japanese factories, modular robotics allow for near-immediate pivots. From FANUC’s yellow robots to custom conveyor arrays, smart plugs and wireless sensors mean new modules click in and data flows instantly.

| Entreprise | Modularity Approach | Implementation Speed | ROI Impact |

|---|---|---|---|

| Toyota | Plug-and-play robots, universal interfaces | Less than 24 hours | High—reduces downtime, improves throughput |

| Yaskawa | Smart sensor modules for material handling | One business day | Strong—customisable, low integration cost |

| Panasonic | Wireless collaborative automation zones | Immediate with centralised config | Excellent—rapid prototyping for new workflows |

Honestly, I think companies outside Japan are only beginning to appreciate how crucial modularity is—integration, not just innovation, wins when supply chain flexibility matters most.9

Strategy 7: Sustainability & Futureproofing

Looking ahead, I’ll be completely honest—Japan’s automation strategies are evolving fast to address environmental sustainability and global regulatory shifts. Three years ago, conversations were mostly about throughput and defect reduction. Now, it’s as much about carbon footprint and “green” supply chains. What excites me? Japanese companies are weaving sustainability into the very architecture of robotics.16

- Energy-efficient robot actuators cut power bills by 15-20%

- Real-time process optimization slashes material wastage

- Automation systems report environmental impact alongside KPIs

- Robotics support circular manufacturing—easy disassembly for recycling

The jury’s still out on whether “zero-waste” factories are achievable globally, but in Japan, dozens of plants have already piloted closed-loop models that recycle components and packaging in-house.

Conclusion & Action Steps

I’ll be honest—writing this, I’m reminded of my first failed attempt to implement a “Japanese style” automation upgrade in a German electronics plant (back in 2016). We skipped the kaizen process, rushed modular integration, and left training for “later.” The result? Frustration, resistance, and wasted budget. This is where I get passionate: Japan’s strategies succeed because they’re holistic and progressive, not just technical. It’s a lesson global supply chains need for long-term resilience.20

- Start with kaizen—empower every level of your team to identify process improvements before adding new tech.

- Integrate modular robotics—prioritise flexibility and ease of upgrade for sustainable expansion.

- Maintain deep supplier transparency—use shared data streams and real-time analytics.

- Train and upskill your workforce—don’t just deploy robots; enable human innovation beside them.

- Measure for sustainability—track environmental impact as a central KPI.

- Learn from Japan’s adaptation curve—patience, feedback loops, and continuous engagement deliver compounding returns.