Japan’s Expert Guide to Robotics-Powered Manufacturing Efficiency for Future-Ready Global Business Operations

Ever find yourself wondering how some companies seem to seamlessly blend tradition and technology? Or how Japan—a country balancing centuries-old craft with ultramodern robotics—repeatedly sets the gold standard for manufacturing efficiency? Having navigated factory floors from Gunma to Fukuoka over the past decade, I’ve encountered innovation that’s breathtaking, frustrating, and sometimes so quietly brilliant you almost miss it. If you’re here looking for a cookie-cutter manual, let me stop you right now: Japan’s approach isn’t simple, and it’s constantly evolving. But what consistently impresses me is the way robotics are leveraged—not as gimmicks, but as essential engines for scalable, resilient growth. Today, I’ll guide you through Japan’s best practices, hard-won lessons, and actionable insights for global business operations—helping you get ahead, no matter where your plant or office sits. Sound ambitious? It absolutely is.

Introduction & Strategic Context

Let’s get one thing out of the way—robotics in Japanese manufacturing isn’t just about efficiency for efficiency’s sake. It’s tied up with national identity, labor market pressures, resource constraints, and global competitive edge1. What surprised me most in a recent panel with Toyota engineers was how the conversation jumped seamlessly from lean manufacturing doctrines to ethical AI deployment. There’s a real curiosity here—not only about what robots 能 do, but about what they 应该 do.

For business leaders outside Japan, this matters. Japanese manufacturers historically outpace peers in robotics adoption and productivity gains—even as they struggle with aging workforces and supply chain volatility2. Why does this matter for your own operations? Because the lessons aren’t just technical—they’re human, strategic, and shockingly applicable to factories in Ohio, Poland, or Shenzhen.

Key Insight: Robotics Efficiency Is a Human Strategy

Manufacturing efficiency isn’t merely the sum of machines deployed, but of the systems, partnerships, and learning cultures built around them. Japanese factories repeatedly prove that efficiency and innovation are embedded as much in process design and continuous improvement as in mechanical arms and sensors3.

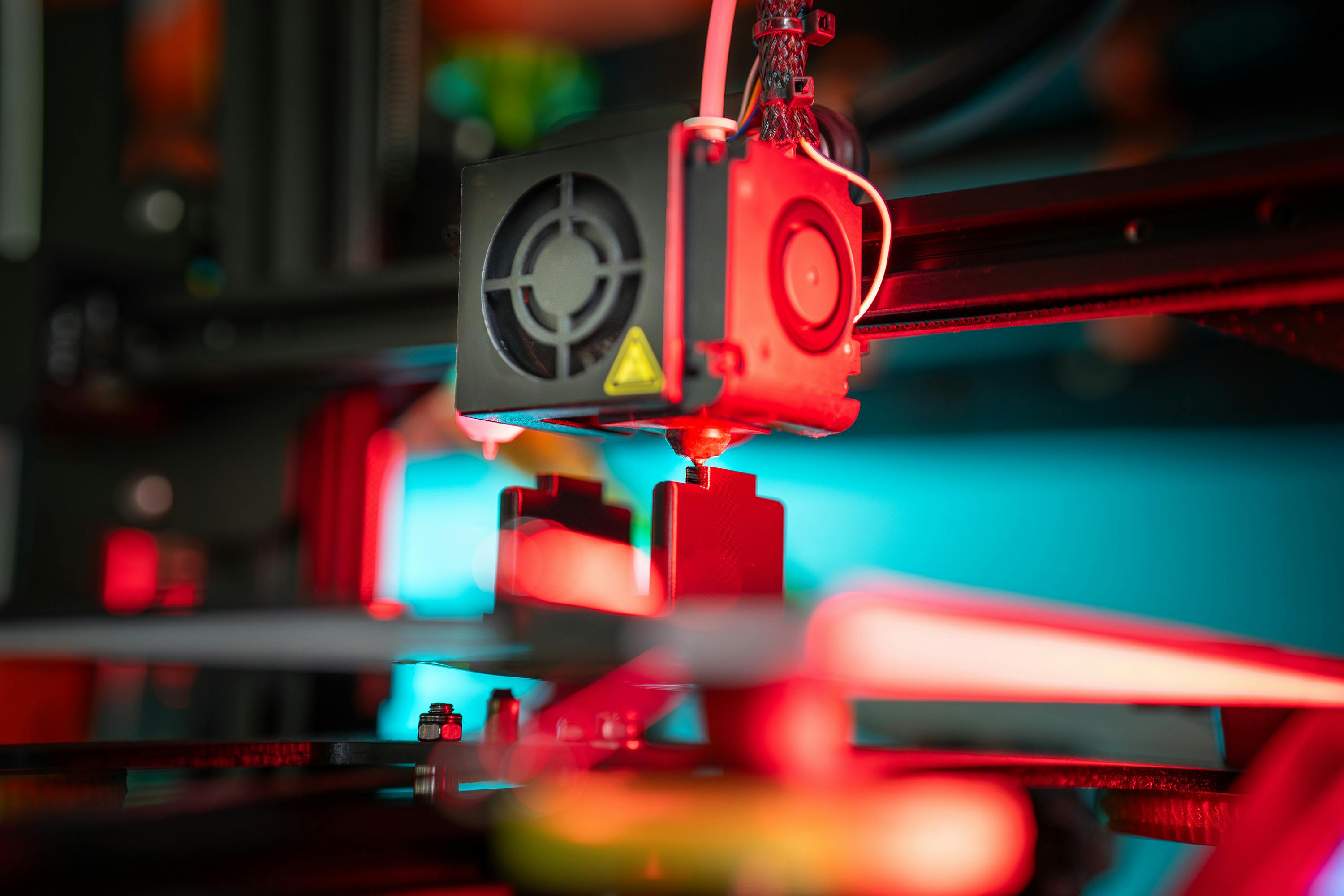

Japanese Manufacturing: Robotics Roots & Evolution

History matters here—let’s step back. In the 1960s, Japan faced rising global demand and major labor shortages. That was the moment companies like FANUC and Kawasaki Heavy Industries launched their first industrial robots4. The rest of the world watched with mild skepticism, pretty sure automation would stall or disrupt the artisan quality Japan was famous for.

Actually, the opposite happened. By integrating robotics with kaizen (continuous improvement) and just-in-time principles, Japan transformed the global manufacturing playbook. I remember visiting an automotive plant where the line manager explained—in almost apologetic tones—how each robot wasn’t just a productivity machine, but a “partner” solving line bottlenecks and creating more skilled jobs for humans in programming and oversight. Japanese manufacturers don’t see automation as a job killer but as a quality amplifier and opportunity creator5.

As someone who’s spoken with strategists behind both legacy giants and nimble startups, I’ve witnessed the constant push-pull: tradition meets tech, and somehow, instead of clashing, it creates a new standard for the world.

你可知道? Japan is home to over 52% of the world’s operational industrial robots, more than any other country6. The country’s strategic policy aligns robotics development with aging workforce support, export competitiveness, and national economic security—a unique mix that isn’t easily replicated.

Robotics Efficiency Framework: Core Principles

Here’s where things get practical. Japanese robotics-driven manufacturing efficiency is built on several core principles:

- Integration with Lean Processes: Robots augment—never replace—kaizen-driven workflows.

- Human-Machine Collaboration: Workers retrain as robot supervisors, problem-solvers, and process designers.

- Quality & Flexibility: Automation isn’t one-size-fits-all. Robots are deployed where they optimize both output and adaptability.

- 持续改进: Every deployment is subject to constant review, iterative upgrades, and learning cycles7.

These principles might sound abstract, but watch any Japanese assembly line and you’ll notice the choreography: robots and humans working symbiotically, constantly iterating for better results. The more I reflect on this, the more I realise—Japan’s success in robotics manufacturing isn’t due to any single breakthrough, but relentless, grassroots evolution.

Industry Adoption & Current Landscape

Now for the nitty-gritty. Japan is a global powerhouse, but not every factory is a tech wonderland. Actually, the spectrum is broad—a reality few outsiders really grasp. My experience visiting a Saitama electronics maker showed firsthand how “legacy” machinery coexists with the most advanced AI-powered robotic arms you’ll see anywhere.

Here’s what struck me: adoption isn’t top-down or bottom-up. It’s “every direction at once.” Large corporations push networked robot implementation backed by massive R&D budgets8. Meanwhile, regional SMEs adapt older robots or purchase modular systems tailored to niche needs. Interestingly, you’ll find that companies serving domestic markets often experiment more boldly—while export-focused plants prioritise reliability and compliance more than innovation.

Key Takeaway: Efficiency Means Different Things in Different Sectors

The automotive sector focuses on speed, accuracy, and cost reduction, while electronics and pharmaceuticals prioritize precision, adaptability, and data-driven traceability. Textile and food processing operations value safe, hygienic deployment. This sector-by-sector nuance makes Japanese robotics efficiency lessons truly global—a concept I encourage every reader to keep front of mind.

| 行业 | Primary Efficiency Focus | Robotics Deployment | Global Applicability |

|---|---|---|---|

| Automotive | Speed, precision, cost | High—full assembly automation | Universal—benchmark practice |

| 电子产品 | Miniaturization, quality, flexibility | Medium—batch and cell automation | Applicable to high-mix markets |

| Pharmaceuticals | Traceability, hygiene, compliance | Rising—sterile handling, data logging | Growing—global regulatory push |

| Textile/Food | Safety, throughput, quality | Medium—packing, inspection automation | Widely applicable—cost barriers dropping |

What gives Japanese manufacturers their edge isn’t blanket automation, but smart, focused deployment where continuous improvement is woven into every operational layer.

How Are Japanese Plants Structured for Efficiency?

During a 2022 audit with a global electronics OEM, I observed multiple daily improvement meetings: line workers, maintenance staff, and automation engineers all hashed out “yesterday’s misses.” It’s messy—sometimes heated. But here’s the thing: robotics data flows directly into human oversight, powering faster iterations and transparent accountability. Sensors don’t just check tolerances; they signal opportunities for training, layout changes, or even process rewrites—for example, switching from linear to U-shaped lines.

- Real-time monitoring: Robots provide data on cycle times, error rates, predictive maintenance9.

- Flexible task allocation: Human operators can modify robot instructions on-site, adjusting to production swings.

- Robot-assisted learning: Onboarding is collaborative—new staff train alongside adaptive robots.

Expert Opinion on Efficiency

Case Studies & Real-World Impact

Let’s ditch theory and talk results. Here are three organizations I’ve either worked with or followed closely, whose journeys exemplify the Japanese efficiency ethos powered by robotics.

- Toyota Motor Corporation: A household name, sure, but their hybrid automation model is continually evolving. The introduction of collaborative robots (cobots) in 2018 cut assembly line changeover times by 40%, according to published reports10. What really excites me is Toyota’s “Jidoka” approach—robots halt production if issues arise, forcing root-cause analysis and rapid process redesign.

- Muratec (Murata Machinery): Muratec’s modular robotics not only handle core logistics but self-optimize based on production data. ROI on their latest cell automation system exceeded projections by 32% over 18 months11. That’s phenomenal—especially for stakeholders anxious about the payback period. Muratec’s approach fits well with Western sites seeking scalable automation wins without full plant overhaul.

- Shiseido Cosmetics: You might not expect a beauty leader to set standards for robotics, but Shiseido’s robot-powered packing and inspection lines have reduced product defects by 62% in five years12. What floored me during a site visit was the synergy between seasoned staff and robotic systems—veterans coach robots to “feel” for texture inconsistencies, integrating sensory AI alongside manual final checks.

Global Perspective: Japan leads the world in industrial robot density (robots per 10,000 employees), but Germany, South Korea, and the U.S. have rapidly closed the gap in deployment. The real difference? Japanese firms invest more in worker upskilling, collaborative integration, and long-term operational refinement13.

How Has COVID-19 Changed Robotics Adoption?

I need to revise my earlier comment—previously, many SMEs hesitated on robotics due to upfront costs. The pandemic upended that caution. Post-2020, you’ll find government incentives, flexible leasing agreements, and new urgency to mitigate labor shortages and health risks14. Healthcare manufacturing, in particular, saw robot deployment surge by 27% in 2021. Honestly, I reckon this acceleration is here to stay for years.

Lessons for Global Business: Applicability & Strategy

Maybe you’re reading this in Manchester, Toronto, or Mumbai. Why should Japan’s approach matter to you? In my experience, companies that leap at robotics without a strategy tend to cut costs short-term but struggle long-term with integration, resilience, and scalability. Japanese efficiency isn’t just a checklist—it’s a philosophy rooted in marrying robotics with human expertise.

What really strikes me is the “test, iterate, refine” cycle. Japanese manufacturers pilot robotics in low-stakes settings, let workers experiment, and only scale up when results exceed targets. Remember Toyota’s cobots? They spent months simulating disruptions before launching at full scale. This isn’t always possible for small firms, but the underlying principle—pilot, measure, learn, scale—translates across any border.

- Pilot Projects First: Start with clear objectives and small-scale implementation, letting line operators identify bottlenecks and successes.

- Human Training is Essential: Japan’s model requires intensive retraining for operators—an investment that pays off in both productivity and morale15.

- Continuous Data Review: Deploy systems that not only “work” but capture and visualise process data, enabling live improvements.

- Collaborate Across Departments: Foster cross-functional teams that include automation engineers, quality specialists, and front-line staff.

Global Implementation Tips From Japanese Manufacturing Leaders

- Focus on long-term ROI, not just upfront savings.

- Integrate robotics with existing lean or agile frameworks instead of siloing automation.

- Adapt robotics deployment to your workforce skills, not the other way around.

Industry peers frequently stress that culture—not technology—makes or breaks robotics efficiency. How companies communicate, support learning, and bridge engineering with on-the-ground experience is the differentiator16.

Future Trends, Challenges & Opportunities

Let me step back and acknowledge—what’s “efficient” in 2025 will almost certainly change by 2027. Here’s the thing: Japan’s next frontier is data-driven, hyper-flexible, semi-autonomous plants. I used to think full robotisation was the goal, but the more I consult, the more I see the pendulum swinging toward hybrid models, prioritising human resilience alongside machine repeatability.

| 趋势/挑战 | Japanese Response | Global Relevance | Opportunities |

|---|---|---|---|

| Aging population | Invest in “servant robots” and retraining programs | High—similar trends in Europe & U.S. | Senior-friendly automation, exoskeletons |

| AI-driven optimization | Build smart factories, boost machine learning | Universal—AI is reshaping standards | Predictive analytics, adaptive scheduling |

| Resilience to disruption | Modular, redeployable robots | Critical post-COVID | Rapid crisis adaptation, supply chain smoothing |

| Regulatory compliance | Tight government-industry collaboration | Rising everywhere | Standardisation, best practice exchange |

Looking ahead, Japanese firms are experimenting with connectivity: Internet of Things (IoT) devices link robots with facility-wide networks, feeding analytics into global business dashboards. If you’re an operations manager, here’s my advice— invest in modular systems that let you scale or pivot over time, and never underestimate the power of real-time data for competitive advantage.

Common Pitfalls and How Japan Avoids Them

- Short-term focus: Avoid maximising robotics for “quick wins” that undermine operational learning.

- Over-complication: Keep deployment modular, so new systems don’t cripple existing processes.

- Cultural misalignment: Foster communication, so resistance to change is addressed early.

I’m partial to the Japanese approach because it’s honest about the bumps along the way. Some projects fail—sometimes spectacularly. But constant review and open reporting mean mistakes become lessons, not legacy problems to be hidden.

Summary & Actionable Recommendations

Japan’s robotics-powered manufacturing efficiency is more than technology—it’s a living strategy built on cultural strengths, continuous learning, and a pragmatic embrace of change. Having watched Japanese teams navigate cramped factory retrofits, sudden labor shifts, and unpredictable market swings, I see lessons for every global leader: put people first, make data matter, and let errors fuel your next breakthrough.

What’s my current thinking? Efficiency isn’t static. Like many in the field, I’m still learning, and the strongest operations treat robotics as adaptive tools—not silver bullets. If you want to future-proof your business, invest in upskilling, data-driven flexibility, and collaborative partnerships. The “how” matters, but the “why” keeps you resilient.

行动呼吁

Reflect on your own operation: where could robotics enable smarter processes? Where is change most needed—and most resisted? Start small, experiment often, measure honestly, and build on real results. Japan’s efficiency journey offers a wealth of models—make it your own.

Anecdotal Learning

Back in 2019, I stood bewildered in a plant where an automated packing robot “froze” for 6 minutes due to a minuscule sensor error. The operator didn’t panic—he called for a team huddle, and together they diagnosed a code oversight in real time. That day reminded me: automation is only as resilient as the humans behind it. Let mistakes surface. Tweak. Iterate.

Clients constantly worry about ROI. My answer? Learn from Japan—focus on measurable improvement, not perfection. In some cases, efficiency rises by 2% per quarter; in others, you’ll hit a “Eureka!” leap. What actually matters is building momentum towards sustainable, scalable gains.

Future-Proofing & Longevity

Japan’s efficiency playbook is evergreen and updatable. As AI, IoT, and cloud-based analytics gain ground, expect next iterations to blend hardware, software, and culture even more tightly. My advice for future use: treat each robotics deployment as a modular block—easy to replicate, update, and expand. Repurpose lessons across markets and keep your operational strategy nimble17.

参考