Japan’s Robotics & AI Playbook: Future-Proofing Manufacturing Now

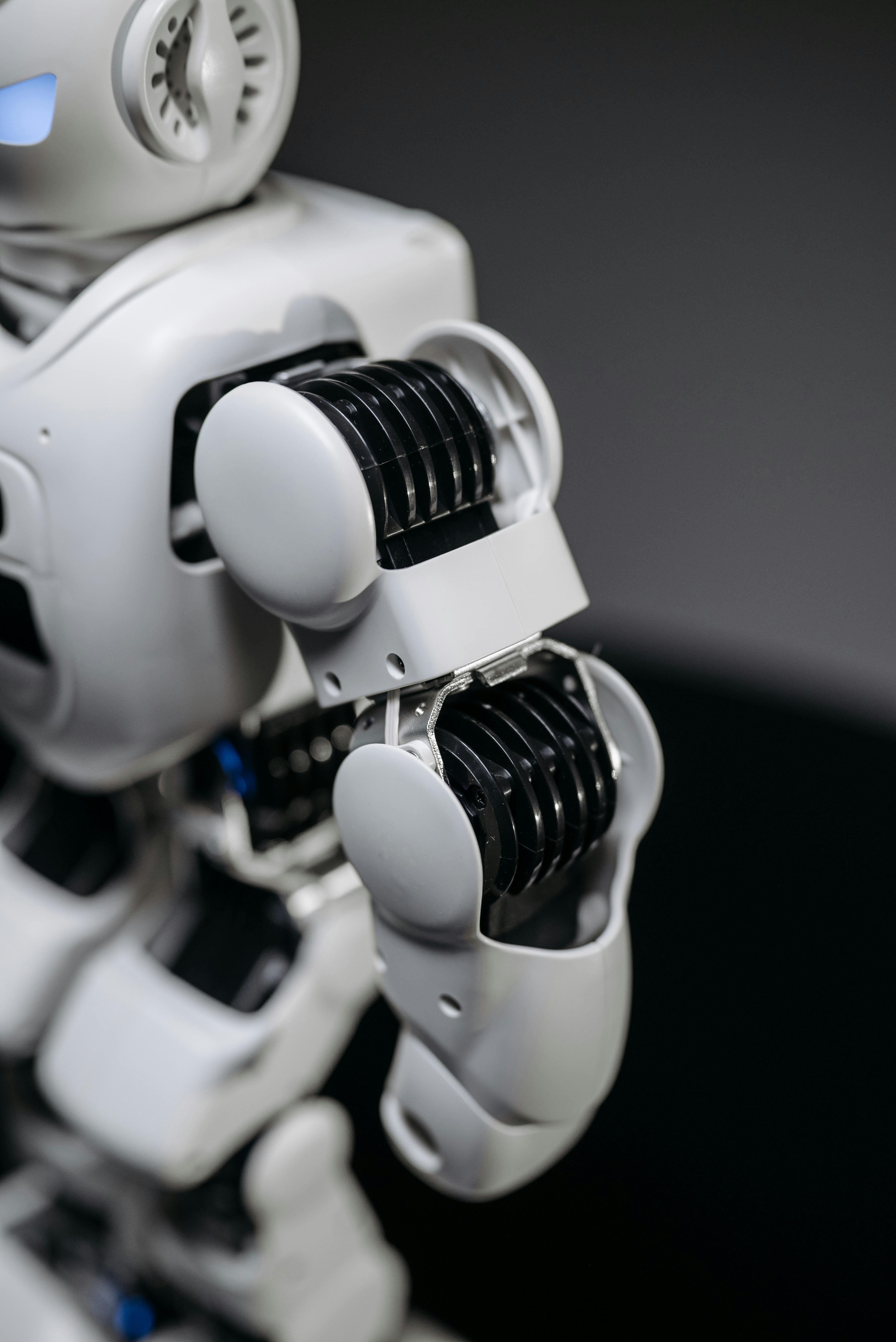

What really struck me the first time I set foot in a mid-sized Japanese machine tooling factory wasn’t necessarily the pristine, humming robotic arms—though, let’s be real, those are pretty captivating. It was the air of relentless improvement, the quiet yet fierce motivation that radiated from everyone, human and machine alike. There’s an assumption out there—especially in Western business circles—that Japan is simply “tech-obsessed,” but that’s a massive oversimplification. Anyone who’s walked the floor during a shift change, seen the digital displays tracking not only efficiency but well-being, or witnessed the ritual of group reflection at the end of a day, knows that this is about more than shiny hardware. It’s a profound fusion of innovation, philosophy, and survival instinct. And amidst the global labor crisis, supply shocks, and AI gold rush, other manufacturing nations are desperate to understand how Japan built— and keeps refining—such a resilient, forward-compatible manufacturing sector.1 Ever notice how so many of today’s automation headlines circle back to things Japan started testing in the 1980s? Let’s unpack why—and what you can adapt, wherever you are.

Why Japan Leads in Robotics and AI Automation

Let’s start with a sobering number. Japan’s working-age population has declined by close to 8 million people since 2000, and it will keep shrinking for the foreseeable future2. Meanwhile, labor shortages in precision manufacturing hit crisis levels long before AI was a catchphrase on the global stage.3 The urgency wasn’t theoretical—it was baked into boardroom conversations, government policy white papers, and, more crucially, the daily “kaizen” meetings at thousands of factories. Necessity, frankly, supercharged innovation.

Key Insight: Automation as Survival, Not Luxury

Unlike some Western settings—where automation is often pitched as a path to higher profits—Japan’s manufacturing automation agenda began as a survival necessity. When the alternative is factory shutdown, there’s no room for half-measures.

During my 2018 visit to a Saitama component assembler, one plant manager put it bluntly: “With so few young recruits, we automate to keep the doors open. But our robots must work in partnership with aging but highly skilled workers.” That tension—between technology and tradition—is the crucible shaping Japan’s unique approach.4

Japan is home to nearly 45% of all industrial robots in operation worldwide today, more than any other country, and accounts for almost one-third of global robot production.5 The gap isn’t just a matter of volume—it’s also about how seamlessly robotics and AI are woven into the heart of business strategy and daily operations.

4 Pillar Strategies Powering Japan’s Manufacturing Resilience

- Human/Tech Symbiosis: Robots aren’t a replacement—they’re skill multipliers for “veteran” employees, built to enhance dexterity and decision-making.6

- Kaizen, but Smarter: The famous incremental improvement philosophy is augmented with AI-powered analytics, real-time feedback, and predictive maintenance.

- Government/Industry Alignment: Policy, R&D funding, and workforce development are tightly interconnected – a deliberate system rather than market chaos.7

- Global Ecosystem Building: Japan’s top robotics vendors (think Fanuc, Yaskawa) don’t just sell units—they co-develop solutions with suppliers, guaranteeing rollout support and knowledge transfer.8

Pause for a second and actually picture that last point. We’re not talking “plug and play automation.” This is an ecosystem where even tiny regional contract manufacturers can access world-class robotics support, and where government incentives nudge collaboration across rivals. In practice? It means adoption is less about “disruption” and more about upgrading the DNA of manufacturing itself.

Cultural DNA: Why Mindset is Half the Battle

I’ll be completely honest: It took me a few years of working with Japanese factory teams—usually over endless green tea and patient observation—before I realised (and sometimes, I still forget) how much of their automation effectiveness is powered by cultural undercurrents rather than just clever coding or best-in-class robotics hardware. The “monozukuri” spirit—a passionate, almost philosophical dedication to making things better, down to the smallest detail—cannot be overestimated9. This isn’t just a business doctrine; it’s a core piece of how work, dignity, and achievement are understood in Japan. Try pushing aggressive automation in a Western plant, and you’ll encounter genuine fear about job replacement. In Japan, the communication centers on respect: new robots are introduced as “colleagues” that extend—not erase—the legacy of retiring craftspeople.

From my experience, when manufacturers outside Japan skip this step—actively addressing the emotional and philosophical impact of digitization—they face backlash, morale slumps, or outright sabotage (I’ve seen all three, believe me). Japan’s approach isn’t perfect, but it buys trust and smooths the road for more ambitious automation later.10

The Human-Robot Balance Sheet (Real Example)

| Role | Before Automation | After Automation | Outcome |

|---|---|---|---|

| Assembly Technician (aged 54) | Manual repetitive assembly—shoulder injuries frequent | Supervises 6 robotic arms, trains new algorithms | Lower injury rate, longer career, higher job satisfaction |

| QC Inspector | Manual visual checks of 1200 parts/day | Uses AI-vision QC interface, flags only disputed parts | Accuracy up 22%, throughput up 35%, staff retrained for advanced troubleshooting |

| Floor Supervisor | Paper logs, relies on memory, low oversight bandwidth | Monitors predictive maintenance dashboards, quick-reacts to alerts | Downtime slashed, crisis averted, less burnout |

The Practical Playbook: Adapting Japanese Automation Tactics

Let’s step back for a second. You’re leading a factory—that could be in Indiana, Bavaria, or Johor—looking to future-proof your business. What’s translatable from Japan’s toolkit, and what isn’t? Here’s the plain truth: Many copy the tech stack (collaborative robots, vision AI, digital twins), but the real gains require process and mindset change that must be sold, not imposed. I learned this the hard way helping a North American client install a “turnkey” Japanese welding cell in their plant. They thought hardware alone would drive ROI. Actually, their biggest pain was staff pushback and implementation breakdown because the cultural groundwork (employee buy-in, respect for upskilling) had been skipped entirely.

Field-Tested Playbook (Adapted from Japanese Practice):

- Audit current processes for “hidden downtime” and skill bottlenecks first

- Pilot small—one cell or function, not a whole line

- Involve multi-generational teams in co-design and feedback loops

- Link digital metrics to process improvement, not staff surveillance

- Schedule “after-action” reviews to surface human impacts candidly

This is where I get passionate. If Western or Asian manufacturers introduce robotics as a form of “cost slashing,” they’ll provoke resistance and waste capital on underused assets. Emulating Japan’s playbook means weaving in upskilling, ritual, and practical acknowledgment of onsite expertise. New tech, old wisdom: It works.11

Case-in-Point: Toyota’s “Smart Factory” Blueprint

Some people still think “lean manufacturing” is just about cutting corners. At Toyota’s Aichi smart plant, I sat in on a “jidoka” (automation with a human touch) session. Here’s what really matters: automation serves as vigilance, not just speed. Every machine is networked for instant problem-flagging, but if a process drifts even slightly out of spec, humans have final authority to halt the line and troubleshoot with the robot’s data. So the “smart” factor isn’t mindless output, but continuous knowledge sharing—a convergence of AI-driven process control and centuries-old commitment to quality.

Key Stakeholders: Who’s Driving Automation Innovation?

- Ministry of Economy, Trade and Industry (METI) – Policy, funding, regulatory guardrails

- Japan Robot Association – Standards, tech transfer, export advocacy

- Keidanren (Japan Business Federation) – Industry, labor, and academic alliance-building

- SME Regional Networks – On-the-ground retraining and tech adoption

The bottom line? In Japan, automation leadership is always collaborative, grounded in consensus, and surprisingly bureaucratic—yet the results routinely push global boundaries.12

Common Pitfalls and Hard-Won Learning Moments

Here’s a confession I need to make: the first time I shadowed a robotics deployment at a Tokyo SME (small/medium enterprise), I believed, naively, that the only challenge would be tuning algorithms and calibrating vision systems. What actually tripped the project up? Social buy-in. People-related friction. The reality is, even Japanese manufacturers—despite decades at the cutting edge—have made serious missteps.13 Let’s be honest, the journey isn’t smooth, and it never becomes “simple.”

- Integration Misfires: Even with top-tier robots, pairing legacy machinery and new AI controllers can create intricate compatibility nightmares. I watched a project stall for weeks due to outdated PLC firmware nobody had documented since 1999.

- Morale Waves: After-automation dips in morale are real, regardless of how well leadership communicates. When a 25-year veteran operator is abruptly reassigned, resistance—sometimes subtle sabotage—can spike.

- Skill Bottlenecks: The myth of “turnkey” is just that—a myth. Skilled programmers and “robot whisperers” become the new linchpins, and there’s always a learning curve.14

What really strikes me (and I have to revise my earlier, overly rosy view): It’s never about hardware alone. It’s always a process of continual feedback, trust-building, and adaptation. And yes—constant troubleshooting.

Japan’s robotics density (robots per 10,000 employees) is the world’s highest at 399, far outstripping second-place South Korea.15 Yet, surveys show 43% of Japanese manufacturers still cite “skills gap” as their number one obstacle to scaling advanced automation. Human capital is always the long-term bottleneck.

Pitfall Avoidance: Practical Checklist

- Start with workforce retraining and communication—before hardware installation

- Budget for debugging, not just for purchase and install

- Secure IT/OT integration expertise—do not assume in-house skills will suffice

- Document every deployment—so mistakes become learning assets, not repeat failures

Looking Forward: Japan’s Next Automation Frontiers

The more I consider this, the more it’s clear: The next phase isn’t about “robots on every line.” Instead, Japan is investing heavily in cognitive robotics, cross-plant AI analytics, and, crucially, the convergence of sustainability targets with digital transformation.16 Ever heard of “GX” (Green Transformation) strategy? It’s reshaping the context in which robotics are being deployed—factories are becoming energy self-sufficient, robots learn to optimize energy cycles, and AI is being used to minimize waste at a scale that simply wasn’t possible before.

- AI for Resilience: Predictive data crunching so granular, it can detect early signs of global supply chain disruption

- Robots as Sustainability Accelerators: Next-gen robots designed for easy disassembly and recycling when obsolete

- Collaborative Networks: Factories sharing anonymized data to accelerate sector-wide improvement during crises (earthquakes, pandemic shutdowns, etc.)

My current thinking (which evolved a lot post-pandemic): The line between “manufacturing” and “software” keeps blurring. At the 2023 International Robot Exhibition in Tokyo, one speaker nailed it: “The question is not ‘Robots or people?’—it’s ‘How do we code culture into our AI so factories still feel like factories?’” That’s a future worth preparing for.

Ready to Dive Deeper?

Get senior leadership around a roundtable. Compare your automation playbook—not just your tech stack, but your culture—to what you’ve seen here. Where are you strong? Where would a Japanese manager suggest a rethink?

Actionable Lessons & Takeaways

- Start process change, not just tech upgrade: Audit your current workflows and ask front-line operators for “pain points.”

- Pilot, measure, reflect: Implement at small-scale, measure impact (including staff morale), review lessons before scaling.

- Skill up, don’t staff down: Make reskilling your headline, not redundancy. The best automation earns buy-in.

- Sustainability isn’t optional: Future automation must slash both labor and environmental cost.

- Build alliances: Tap into vendor, government, and cross-industry knowledge—not just consultants—for robust support.

Discussion Prompt

What’s the one lesson from Japan’s automation journey that would (or wouldn’t) work in your local context? Where do you see your plant’s greatest point of resistance or opportunity? Take a minute—write it down. Start the real conversation. These aren’t “Eastern only” strategies; they’re blueprints for the next manufacturing era.

Professional Call-to-Action

Curious to see how your facility’s automation strategy measures up? Gather your most diverse team—old hands, new hires, management, even vendors—and audit both process and culture. Use Japan’s model not as a prescription, but as a mirror. The future belongs to those who adapt with clarity, humility, and relentless learning.

References

Sources and Further Reading