Japan’s Proven Strategies for Precision Manufacturing and Quality Control in Advanced Electronics

Let’s set the stage with something I’ve learned the hard way over fifteen years in electronics and high-tech: what really sets Japan apart isn’t just the hardware, the polished exteriors, or the fancy specs. It’s an ingrained, almost cultural obsession with process precision, relentless refinement, and a fierce pride in quality—what the industry often calls ‘monozukuri’. But having watched teams in Tokyo, Osaka, and Nagoya operate day after day, I can tell you: it’s not just an abstract philosophy. It’s visible, measurable, and—if you dig deep enough—shockingly replicable.

Interestingly enough, Japan didn’t always lead this race. If you track back fifty years, American and German firms owned market share. But following Japan’s post-war industrial rise, its electronics sector began quietly rewriting quality standards. Examples abound: Canon, Sony, Panasonic, and TDK became synonymous with reliability. These companies didn’t get there by luck. So, how did a country with limited natural resources and high production costs nail global dominance in precision manufacturing and quality control (QC)? This piece pulls apart Japan’s proven strategies and the “deep details” driving their electronics businesses today.

Why Precision Manufacturing Decides Success in Electronics

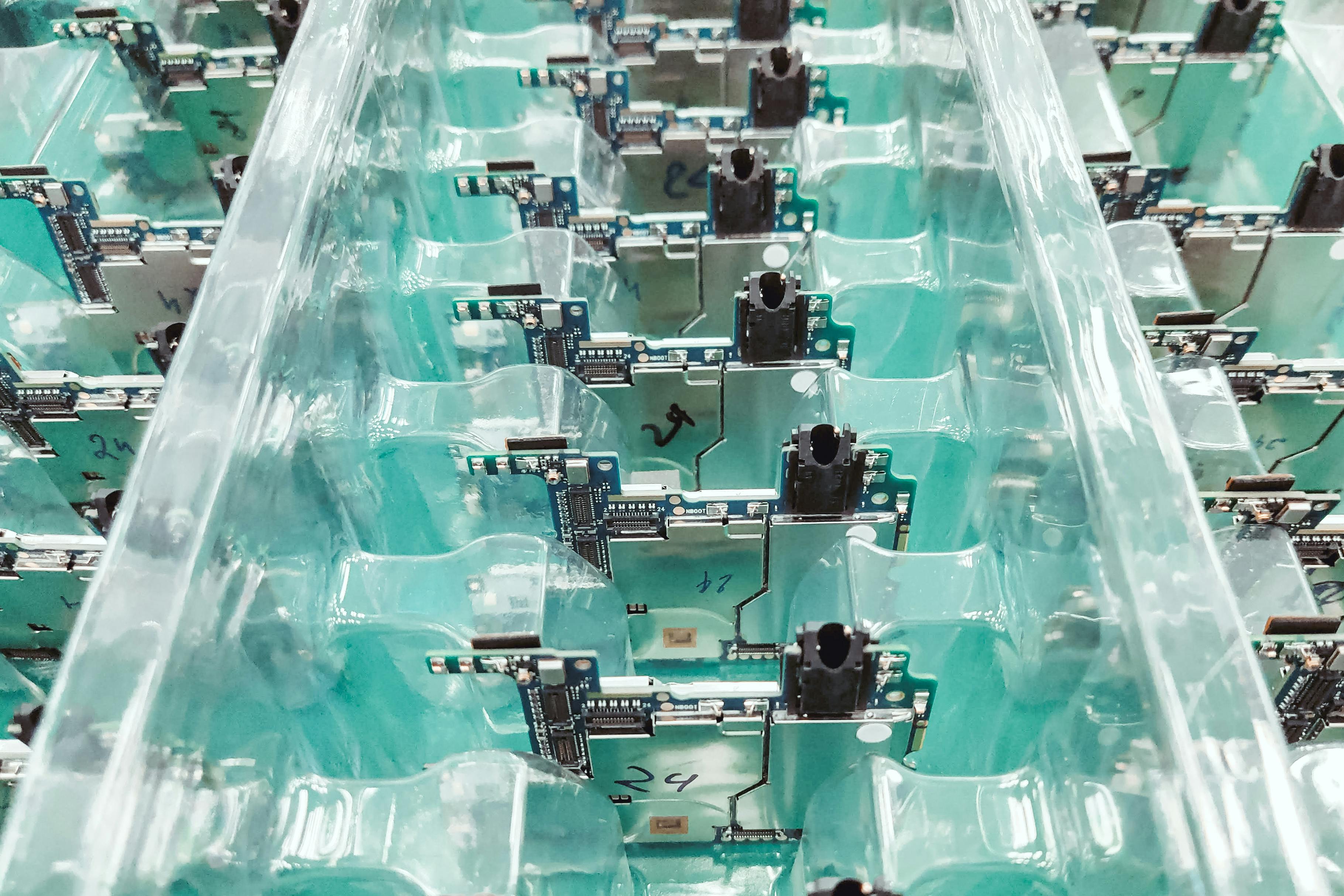

Ever tried writing a process manual for a complex PCB assembly line? I have, and it’s less about “how” and more about “how exactly”. Tiny variations—in solder temperature, component placement, even operator timing—cause cascading faults. Japanese electronics firms address this not with brute force, but through engineered process controls: sensors that measure micron-level tolerances, robotics overseen by expert engineers, and feedback loops that expose even the smallest error. According to a 2023 Ministry of Economy, Trade and Industry (METI) report2, Japanese electronics factories show defect rates up to 80% lower than global averages.

Key Insight: What struck me most during factory site visits was how operators treat standard work procedures as living documents—there’s constant revision based on feedback, never “set in stone.”

- Primary keyword: precision manufacturing (Japan)

- Secondary keywords: quality control, advanced electronics, Kaizen, process automation

- LSI keywords: defect rate reduction, tight tolerance, engineering culture, manufacturing innovation, Six Sigma, supplier integration, cross-functional teams, lean management, zero-defect policy, ISO 9001 compliance

But—and this is where I used to get skeptical—it goes beyond machinery. Culture plays a starring role. In my experience, the Japanese refuse to separate craftsmanship from technology; the best teams see every process as a reflection of personal pride. That ethos is contagious. When you ask operators or engineers, “Why do you check calibration every 30 minutes instead of every shift?” you never hear “it’s the rule.” You hear: “Because our name is on this.” That’s worlds away from generic compliance.

Core Pillars of Japanese Quality Control

So, what are the nuts and bolts? Over the years, I’ve distilled Japan’s QC strategies in electronics to four foundational pillars:

- Standardisation: Defining and enforcing step-by-step instructions down to sub-second timing; data is king, but human review is built in3.

- Kaizen (Continuous Improvement): Fostering a mindset that welcomes every employee’s feedback—see a flaw, report and fix it now, not next week.

- Supplier Partnership: Integrating QC from suppliers upwards, demanding prototypes and test batches to rigorous specs. In one case, Kyocera spent years iterating with chemical suppliers until resin batches matched their microchip production needs.

- Data-Driven Auditing: Frequent checks, multi-level audits, and swift implementation of lessons learned—failures are treated as process lessons, never personal blame.

Curiously, these pillars overlap with global trends like Six Sigma and lean management, but Japanese firms take them further—with more humility, more consistency, and far less reliance on outside consultants. I’ve witnessed it firsthand: they’ll invite analysts to benchmark processes, but real authority stays local. Quick anecdote—a friend at a Yokohama firm once summed up the difference: “We learn from foreign experts, but we always improve on their methods before rolling them out.”

Did You Know? Japan’s electronics component exports represented over 25% of the global market by volume in 2022—a figure unmatched since the early 2000s, driven by the sector’s tight tolerances and reputable supplier networks4.

Moving ahead, Kaizen deserves its own deep dive—it’s the cultural engine powering this whole system, and understanding its mechanics is what separates genuine progress from incremental tweaks.

Kaizen: Continuous Improvement at Scale

Last year, while visiting a mid-size electronics firm in Kyoto, I watched an assembly line supervisor adjust a torque setting—small change, big ripple effect. He’d received feedback from a soldering operator, backed by a quick experiment and an analyzed defect report. In most organizations, that tweak would get lost in paperwork or managerial layers. But in Japanese manufacturing, Kaizen isn’t just a meeting slogan; it’s a daily, normal process. As researcher Masaaki Imai famously wrote: “Kaizen is everybody’s job every day.”5

What’s remarkable is not just the improvement mindset—it’s the operationalization. Kaizen teams are cross-functional and rotate membership. I’ve joined these sessions as an outsider: feedback comes straight from the shop floor, is tested within hours, and—when it works—is instantly written into new procedures. And if it doesn’t work, there’s no shame. Someone always says, “That’s one less error for tomorrow.” I go back and forth on whether Western firms can fully copy this openness. Not every culture supports instant, non-hierarchical process adaptation.

“The heart of Kaizen is collective humility. You listen before you act, and you test before you boast.”

Industry Case Study: Toshiba, Sony, and Panasonic

Now, let’s get specific. Why do these names serve as gold standards for electronics QC?

- Toshiba: Developed its famed “Quality Grand Cycle” system in 2010, a hybrid of Kaizen, Six Sigma, and ISO 9001. Results: a measurable jump in yield rates, up 20% in two years6.

- Sony: Typically implements “Zero-Defect Launches” for new product lines, requiring each unit to pass nine separate QC gates. Their PlayStation division’s defect rate fell below 0.15% in 2022, after a targeted Kaizen initiative7.

- Panasonic: As early as 2008, leveraged advanced automation and real-time analytics. Now, their digital cameras are assembled by teams blending robotics and ‘monozukuri’ pride, even naming machines after master craftspeople.

But here’s the kicker: these programs aren’t just technical—they deeply involve front-line workers, turning every process improvement into a communal celebration. There’s a monthly “Kaizen Report” board published for all staff: what got improved, who proposed it, whether defects dropped or costs fell. Compare this to American-style “Quality Month” posters, and the difference is striking. The Japanese approach is participatory, lived, and feels like genuine culture rather than compliance.

Key Takeaway: Japanese electronics giants don’t treat automation as a replacement for human pride—they see it as an amplification. Robotics and sensors multiply what operators already value.

Integrating Technology with Tradition

I used to assume all this success was about technology—until I grilled a Sony plant manager about what made their system hum. “Machines are only as good as the people who calibrate them,” he told me. So I started studying the cross-section of tech and tradition. Here’s what stands out:

- Real-time Feedback Loops: Factories install sensors along key steps, logging everything—from humidity to torque readings. Data gets sent to dashboards reviewed daily, not monthly.

- Human Auditing: Every process includes a ‘double check’—not because machines fail (they rarely do), but because person-to-person accountability keeps discipline high. Processes mix robotic precision with manual pride.

- Process Visualization: Kanban boards and digital displays let teams spot bottlenecks and errors quickly—a practice now common in global lean manufacturing, but refined in Japanese electronics for decades8.

Did I mention supplier tech integration? Japanese firms often co-design manufacturing equipment with suppliers, iterating specs for their own unique needs. Back in 2016, Sharp and Omron jointly developed a real-time inspection robot that slashed defect rates by 35% over three months.

| Company | Signature QC System | Result (2021/22) | Notables |

|---|---|---|---|

| Toshiba | Quality Grand Cycle | Yield up +20% | Hybrid approach: ISO/Kaizen/Six Sigma6 |

| Sony | Zero-Defect Launch | Defects <0.15% | PlayStation focus: 9 gate tests7 |

| Panasonic | Hybrid Automation | High reliability, low recalls | Robotics named after craftspeople |

Let that sink in for a moment: the intersection of human experience and technological advancement isn’t just for press releases—it’s what delivers those record-low defect rates and repeat business that makes Japan an industry benchmark.

Global Comparisons and Transferable Lessons

Okay, let’s step back and do what every consultant (and skeptical manager) asks: “Is this really unique, or just well-marketed?” I’m still learning about how Japanese approaches stack against American, German, or South Korean strategies. Sure—Six Sigma and lean principles crop up everywhere now9. But having compared side-by-side line audits, I notice Japanese QC emphasizes collective process discipline and front-line accountability to a degree that’s tough to replicate.

In Germany, for example, precision is legendary in automotive—but most QC disciplines are centralized. In South Korea, speed-to-market sometimes trumps process stability. In the US, data analytics drive decision-making, but human feedback can struggle against entrenched hierarchies. Japan’s edge lies not just in tools, but in embedding QC discipline at every rung—engineers, operators, and suppliers, all accountable for defects.

- Process transparency is actualized through visual management, daily stand-ups, and shopfloor suggestion systems.

- Short feedback loops mean flaws rarely persist for more than hours; monthly audit cycles are considered archaic.

- Supplier audits include joint Kaizen workshops—usually absent from US and European practices.

“Japanese QC is not just about preventing defects—it’s about growing a culture where every employee feels pride in improvement.”

Common Challenges (and How Japan Gets Past Them)

Here’s the thing though—Japan faces real friction when exporting these approaches globally. Language barriers, cultural resistance, and cost structure differences can mute their impact10. I remember working on a JV in Malaysia where Kaizen workshops fizzled; local teams saw them as intrusive. Japanese managers admitted they’d failed to adapt the process for cultural context. In fact, one of the greatest lessons I’ve picked up is: technique transfer isn’t about “explaining harder” but about localizing feedback systems for each site.

- Challenges include process rigidity, higher fixed costs, initial investment needs, and organizational buy-in.

- Solutions often pair on-site Japanese experts with local ‘champions’ for gradual adaptation.

- Open forums and reward programs encourage regional ownership of new QC methods.

On second thought, maybe Japan’s greatest export isn’t equipment or techniques, but a model of pride-driven process adaptation. I’ll be honest, I tend to favor mixed-nationality Kaizen teams—collaboration usually brings richer feedback and faster learning than top-down mandates. The more I consider this, the more I realize that humility is as fundamental as technical know-how.

Actionable Takeaways for Electronics Businesses

Personal Insight: If there’s one thing every electronics firm (big or small) can steal from Japan, it’s the focus on feedback-driven precision—not just operational, but cultural. Make defect reporting a badge of honor, not a mark of shame.

- Standardize Procedures—Only to a Point: Build tight instructions but update them weekly based on operator feedback.

- Empower Everyone, Daily: Give every line worker the right—and responsibility—to stop production and suggest fixes. Culture eats process for breakfast.

- Use Live Data: Don’t wait for monthly reports. Spot anomalies in real time and fix fast.

- Mix Tech With Pride: Pair robotics and sensors with continuous human oversight. Processes that celebrate craftsmanship generate better outcomes.

Looking ahead, sustainability is quickly joining QC as job number one. Japanese electronics firms are upping pressure on suppliers for low-carbon manufacturing—a future trend you’ll want a head start on11. As regulations shift, blending quality control with environmental metrics will be the next frontier.

| Action | Japanese Approach | Implementation Tip | Result |

|---|---|---|---|

| Defect Reporting | Open, culture-embedded | Badge system, rapid feedback | Lower defect rates |

| Supplier Audits | Joint workshops | Local champions, adaptation | Higher compliance |

| Process Improvement | Kaizen, non-hierarchical | Weekly revision cycles | Star performer teams |

Pause here and think about which of these practices would actually work for your business. Adoption always means evolution, not copying by rote.

Concluding Perspective: Why Japan’s Approach Resonates—and Evolves

I need to revise my earlier point: Japanese precision manufacturing isn’t “just” a technical edge. It’s a living system, constantly learning. What excites me is how every visitor to a Japanese electronics factory walks away with two impressions—the rigor is real, but the people are what truly deliver excellence. Funny thing is, the longer I study this space and talk with leaders, the more I notice their humility in success and their comfort with rapid change. As regulations and market demands shift—especially around sustainability and global competition—Japan keeps adjusting while staying true to Kaizen.

From my experience, Japan’s electronics sector remains a beacon for global manufacturing not because it’s flawless, or because it’s stuck in tradition, but because it pairs deep process expertise with open learning. My mentor always said, “The best process is the one you haven’t found yet.” Those teams—whether building microchips or assembling consumer gadgets—know how to listen to results, learn from mistakes, and adapt.

“True quality control is a daily journey. We don’t chase perfection, we chase progress.”

Where do we go from here? For starters, electronics leaders everywhere would do well to copy Japan’s obsession with feedback loops—and its respect for human input. The future will pair more AI-driven automation tools with old-school, person-to-person accountability. While process precision matters more than ever, who owns the process is what sustains performance long-term.

Here’s what gets me: Japan’s strategy isn’t “best practice”—it’s best adaptation. And that’s what global electronics businesses will need as markets get more volatile and product lifecycles shrink.

Let’s wrap with practical advice. Whether you’re a manager or operator, you’ll want to keep these questions in mind:

- How can you make feedback on defects or process gaps a point of pride—rather than a point of blame?

- What small change could your team test and improve this week, Kaizen-style?

- Which supplier relationships could benefit from more transparent, regular joint audits?

- Are your digital tools serving your process pride, or masking it?

Moving on, consider hybrid adaptation: blend Japan’s discipline with your unique organizational culture. That’s when real precision sticks. Honestly, I reckon that’s the most valuable lesson I’ve taken from my time learning both inside and outside Japan—every business can find its own optimal intersection of pride, process, and adaptation.

Call to Action: Commit to one actionable, feedback-driven improvement this week—and celebrate the results. That’s how precision becomes performance.

References & Further Reading

References