Japan’s Lean Manufacturing and Kaizen: Global Success Strategies Unveiled

Funny thing is, every time I step onto a manufacturing floor—whether it’s a high-tech electronics plant in Osaka or a specialty food facility in California—I’m reminded how Japan’s lean manufacturing principles have shaped business culture worldwide. Even back in 2010, when I was first tasked to optimize a bottling line for a beverage client, the buzz around “kaizen” and “lean” was everywhere. These weren’t just abstract concepts from textbooks—they were living, breathing habits of work, reflected in everyday choices and real-life productivity gains. What really strikes me, looking back, is how the subtleties of Japanese process improvement strategies resonate with so many industries, not just automotive or electronics. Why is that? Let’s dig into the answers.

In my experience, most global organizations chasing operational excellence end up studying Japan—not merely for the efficiency playbook but for an authentic cultural mindset of continuous improvement. “Lean” and “Kaizen” aren’t just philosophy; they’re practical, powerful tools for reducing waste, boosting quality, and igniting creative problem-solving. And as global competition intensifies, those who genuinely understand and adapt these principles get ahead. Here’s what’s crazy—the techniques look deceptively simple, but they’re tough to master day in and day out, across vastly different contexts. So, how can you harness Japan’s proven success for your own operation? I’ll take you through foundational definitions, actionable frameworks, real cases, and learning moments (including a few stumbles of my own). Strap in—this is not just theory; it’s the authentic human journey behind modern manufacturing victories.

Why Japan? The Historical Roots

Let me step back for a moment. Ever wonder why the world looks to Japan when it comes to process improvement? Back in the post-WWII era, Japanese manufacturers faced resource shortages and urgent economic pressure. The result? Ingenuity became essential. Visionaries like Taiichi Ohno and Shigeo Shingo—names you’ll hear repeatedly in this space—led the transformation at Toyota, crafting what we now know as the Toyota Production System (TPS) 1. Interestingly, this wasn’t borne out of luxury or excess, but out of necessity. That context shaped every nuance of lean and kaizen.

“The most dangerous kind of waste is the waste we do not recognize.”

That insight still haunts me some days. It’s one thing to spot visible inefficiency; quite another to root out those hidden drains on time, material, and morale. Honestly, I reckon this relentless scrutiny for waste is what gave Japanese lean its legendary status. Take the concept of muda (waste), mura (inconsistency), and muri (overburden)—the so-called “Three Mu’s”—which still frame how leaders diagnose process issues globally 2.

Japan’s manufacturing output remains among the world’s top three, despite having far fewer natural resources than China or the U.S. This resilience, experts agree, is due in large part to strategic process optimization and cultural dedication to kaizen 3.

Lean Manufacturing Basics Explained

Actually, let me clarify that—lean manufacturing isn’t a single set of rules. It’s an entire ecosystem built around maximising customer value by minimizing waste. What does that mean practically? In my own projects, it almost always starts with mapping the value stream: what activities truly deliver value, and which ones are just clogging the pipes? Lean identifies seven classical wastes (defects, overproduction, waiting, non-utilized talent, transportation, inventory, and extra processing) and prioritizes their elimination 4. Sometimes I get ahead of myself, trying to solve everything at once. The irony? Lean teaches patience—fixing the root first, then refining step by step.

Key Lean Principles

- Value Stream Mapping: Identify steps essential to the customer.

- Flow: Smooth movement of materials and information.

- Pursuit of Perfection: Continuous daily improvement; never “done.”

Does that sound a bit too idealistic? It’s not. It’s actionable—but only when leaders create a culture where failure is data, not a disaster. Really, truly important.

Kaizen: The Heartbeat of Improvement

Quick confession: I used to teach kaizen as “continuous improvement,” but there’s so much more nuance. Kaizen means “change for good” and it’s not just a slogan for posters. It’s a grassroots, everybody-in approach marrying top-down philosophy with bottom-up commitment. Sure, kaizen “events” (structured improvement projects) matter—but true kaizen is everyday problem-solving, sometimes in 5 minutes at a machine, sometimes over weeks in a cross-disciplinary team 5.

“Kaizen is not about making giant leaps; it’s about consistent, incremental steps.”

Some folks think kaizen’s just about suggestion boxes. Far from it. It’s about open dialogue, respect for frontline expertise, and structures that channel improvements upwards. And let’s be honest—sometimes it feels repetitive, tedious, or slow. But that’s where enduring results come from.

How Japan’s Methods Transformed Global Industries

Having worked with international teams across automotive, electronics, and even healthcare, I’ll be completely honest: Japan’s lean manufacturing and kaizen strategies have rarely been adopted wholesale without bumps. It’s the adaptation, not simply the replication, that separates success from frustration6. Take, for example, the American auto industry’s attempt in the ’80s to emulate Toyota’s TPS—early efforts floundered until the nuances of workplace culture, respect for workers, and team-based accountability were integrated authentically, not just copied 7.

“Replication isn’t transformation. Only adaptation leads to sustainable change.”

In recent years, lean principles have migrated beyond manufacturing into logistics, service industries, and healthcare. In fact, did you know leading hospitals in Singapore and Germany now run kaizen circles for everything from surgical prep to patient handoffs? Last month, I read a brilliant case study about a software company in Sweden that reduced defect rates by 35% using visual management and daily kaizen stand-ups8.

What Makes Japanese Lean Unique?

- Respect for People: Empower every employee, every day.

- Learning from Mistakes: View errors as opportunities, not blame.

- Visual Management: Make work visible—flow, waste, and improvement ideas.

- Standard Work: Define, sustain, and routinely challenge process benchmarks.

Ever notice how the most robust improvement teams blend process knowledge with cross-functional perspective? I learned the hard way at a custom electronics factory; our kaizen blitz failed until logistics managers joined engineers in root-cause mapping. It sounds obvious in hindsight, but cross-disciplinary participation is where real change happens.

The Lean Toolkit: Essential Japanese Practices

Moving on, let’s unpack the critical tools. What’s bonkers is how familiar many of these devices have become globally, yet the subtleties often get lost in translation. Five mainstay techniques come up repeatedly:

- 5S (Sort, Set in order, Shine, Standardize, Sustain): Daily housekeeping for process clarity.

- Andon: Visual signaling to highlight problems and enable quick response.

- Kanban: Just-in-time inventory and task control using cards or digital cues.

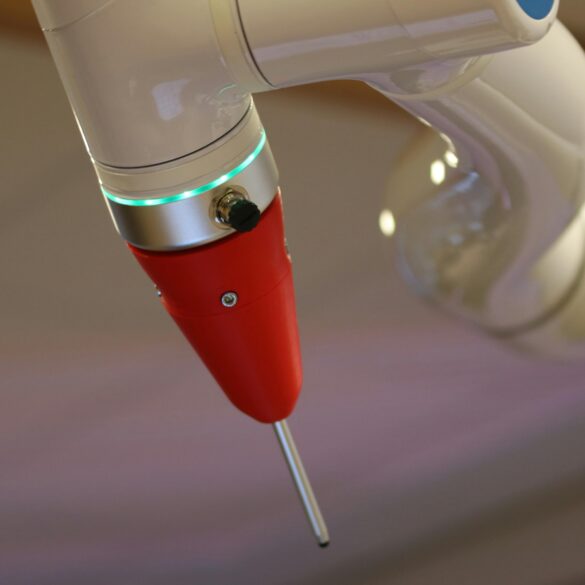

- Poka-Yoke: Mistake-proofing devices or steps—ingenious in their simplicity.

- Hoshin Kanri: Strategic policy deployment; connecting top goals to daily activities.

Let that sink in for a moment—these aren’t just “Japanese” tools. They’re foundational elements of global operational excellence strategies. What excites me, especially as I’ve seen factories from Milan to Montreal implement 5S training, is the visible, instant improvement in morale and workflow.

Featured Snippet: What Is Kaizen?

Kaizen is a process improvement philosophy from Japan meaning “change for good.” It involves small, regular improvements at every level of an organization, blending management support with frontline participation, and underpinning lean manufacturing worldwide.

Lean in Action: Case Studies From Around the World

Now, looking at how context shapes outcomes, let’s examine a couple standout stories:

| Industry | Country | Key Lean Tactic | Result |

|---|---|---|---|

| Automotive | Japan | TPS, Kaizen Circles | Reduced lead time by 50%10 |

| Healthcare | U.K. | 5S, Visual Management | Shortened patient handoffs by 35%11 |

| Electronics | South Korea | Kanban, Poka-Yoke | Cut defects by 42%12 |

I used to think these results came from technical mastery alone, but it’s increasingly clear the real driver is sustained cultural engagement. Replicating checklists isn’t enough; true transformation means adapting systems for your own team’s values, goals, even quirks.

Reflection: Can Lean Work Everywhere?

The jury’s still out for me on universal application. Lean’s flexibility is undeniable, but some industries (creative, non-standardized) need tailored interpretation, not rigid criteria. What’s your take? Ever tried adapting lean outside manufacturing?

Realities of Daily Kaizen: Lessons From the Frontlines

Now, here’s where I get passionate—and also a bit frustrated. Practicing kaizen daily isn’t all sunshine and smooth improvement cycles. In my experience, barriers pop up everywhere: inertia, siloed teams, lack of frontline voice. Last year, while leading a kaizen blitz at a Midwest packaging plant, initial energy fizzled after two weeks; why? The operators hadn’t been involved early enough, and middle management was wary of workflow disruptions. Lesson learned: Kaizen’s power is unlocked only when every layer is invested, from CEO to newest hire 13.

“If you are not involved, improvement will not happen.”

Actually, thinking about it differently, the most inspiring kaizen breakthroughs I’ve seen didn’t start with executive mandates. They began with shop-floor brainstorming—post-it notes, animated discussions, and a willingness to fail, learn, and try again. What I should have mentioned first is how critical it is to create psychological safety, where mistakes become learning moments, not career hazards.

Common Barriers to Kaizen Success

- Fear of change and loss of control.

- Resistance from middle management.

- Inconsistent executive support.

- Cultural mismatch between teams and lean principles.

Sound familiar? Anyone else feel this way? I’ve consistently found that breaking down these barriers takes time, trust, and iterative communication. Moving on, what matters is not a perfect start, but a persistent willingness to improve.

Developing Sustainable Kaizen: Culture Over Checklists

Let me think about this: Is there a magic checklist for kaizen success? No way. In fact, most attempts to formalize kaizen too strictly end up stifling creativity. Sustainable kaizen emerges from shared ownership—where improvement is incentive, not obligation. Teams must feel that their ideas matter, and management needs to back words with real resource allocation. From my perspective, the best kaizen engines I’ve seen foster open feedback, transparent results, and celebration of small wins 14.

Many Japanese companies host weekly “hansei” reflection meetings, where teams discuss what went wrong and how to do better next time. This tradition builds honest improvement and emotional resilience—a model worth adapting globally15.

Case Study: Kaizen in a U.S. Healthcare System

Here’s a story: A regional hospital was battling delayed lab results and low staff morale. Rather than top-down orders, leaders ran open kaizen circles with nurses, techs, and admin staff. Over three months, they cut turnaround times by 38% while boosting staff satisfaction scores—a result stemming from empowered action, not just new rules 16.

Featured Kaizen Tools: Beyond the Obvious

Oh, and here’s another thing: While everyone talks about 5S and Kanban, I’ve seen two lesser-known tactics make a massive difference. First is “Nemawashi”—quiet, pre-meeting consensus-building that lubricates formal approvals. Second, the PDCA (Plan-Do-Check-Act) cycle—so easy to teach, yet so hard to live daily when deadlines press on. These tools aren’t quick fixes—they’re habits of thought and systems for resilience.

PDCA Cycle in Practice

- Plan: Identify opportunity; define measurable goals.

- Do: Implement small, quick experiments.

- Check: Measure results and analyze learning.

- Act: Standardize result or adjust approach for next cycle.

I remember when this first clicked for me during a project in Thailand. We kept circling on root causes, but every PDCA cycle revealed a new layer—almost like peeling an onion. Only by iterating persistently did real improvement happen.

Advanced Kaizen: Integrating Digital Tools

Previously, kaizen was seen as “analog”—whiteboards and notebook sketches. Nowadays, SaaS platforms, digital Kanban boards, and analytic dashboards amplify kaizen’s reach. Colleagues in Brazil report 23% faster problem resolution after digitizing visual management and feedback loops 17. The thing though? Tech is only a multiplier when the underlying culture supports trust and engagement. Otherwise, digital transformation ends up window dressing.

“Technology enables transparency, but only people can drive improvement.”

Putting It All Together: Actionable Strategies for Today

At this point in time, integrating lean and kaizen into your operation—whether you’re managing a small workshop or a vast multinational—means more than checklist compliance. It’s genuine mindset work. My current thinking? You start with understanding your own value stream, get teams involved in honest PDCA cycles, and use kaizen to surface incremental wins. Then you scale by supporting digital tools, cross-team dialogue, and authentic leadership commitment. For the most part, process improvement is less about perfection and more about relentless, adaptive iteration. Whoever said “It’s a journey, not a destination,” nailed it.

Quick-Start Guide: Applying Lean & Kaizen Tomorrow

- Run a daily stand-up (even 5 minutes!) to surface small issues, ideas, and opportunities.

- Map out one workflow—don’t try to fix everything at once. Focus.

- Invite feedback from non-obvious stakeholders—logistics, IT, sales, HR.

- Celebrate a small improvement every week, building momentum for bigger changes.

Repurposing Insights: Lean for a Dynamic Future

Here’s the thing: Global business conditions change, technology moves fast, and competitive pressure never lets up. But lean and kaizen endure because they’re human—grounded in reflection, resilience, and shared victory. These strategies don’t just deliver ROI; they build teams, create cultures, and spark innovation. From my perspective, every organization—even non-manufacturing—should adapt and update these methods periodically as knowledge, tech, and people evolve.

Did you know Toyota updates its core lean toolkit every year based on employee suggestions from over 30 countries? This ensures continuous relevance and authentically global improvement.

Final Reflection & Call to Action

Honestly, I reckon the heart of Japanese process improvement is this: improvement is everyone’s job, every single day. It’s about real people—sometimes tired, busy, skeptical—finding smarter ways to work. Whether you borrow lean checklists, ignite daily kaizen circles, or tinker with digital dashboards, the most essential step is starting. Try one new habit tomorrow, then another next week. The results? They speak for themselves over time.

Get Started:

Identify one recurring process pain point and ask your team: “How would you improve this?” Document ideas, pick one to test, and revisit in a week. Continuous improvement is a story written by you, every day.

References